lmpcpump

Central Heating Magnetic System Boiler Filter 22mm Valves

Central Heating Magnetic System Boiler Filter 22mm Valves

Couldn't load pickup availability

Royal Mail 24 Hours Next Day Delivery. Same day dispatch for order placed before 12pm.

Instruction Manual

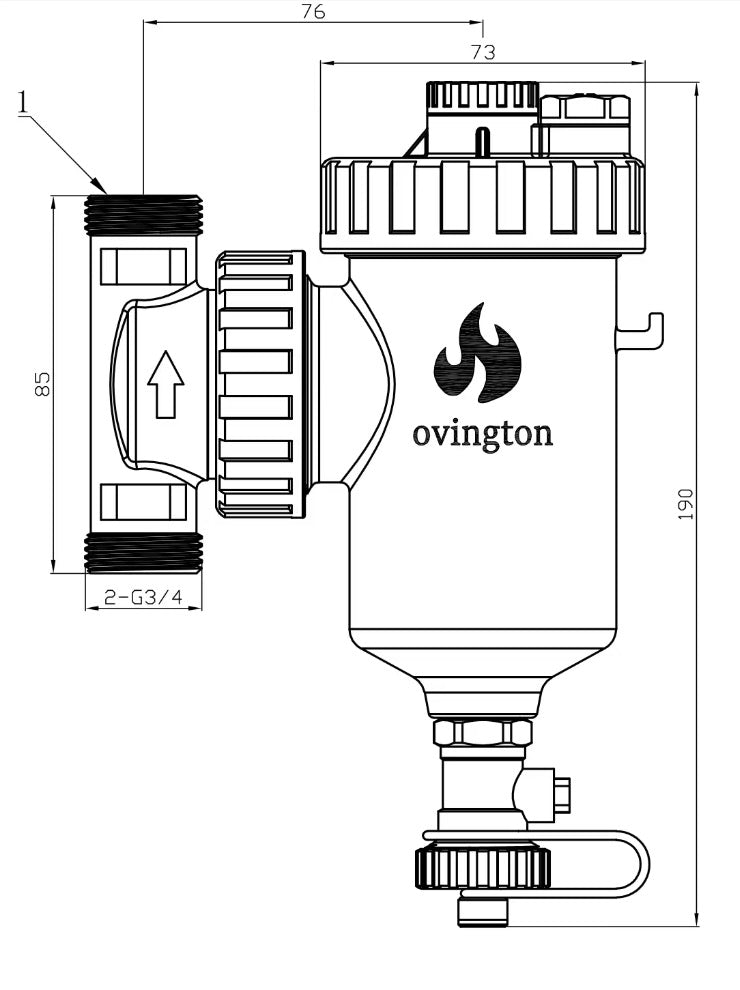

Magnetic Filter G3/4”’, for Central Heating Systems.

(1] Guarantee:

Thank you for your purchase of a Magnetic filter . We want you to continue getting the best performance from it so this handbook includes information on safety, handling, and care. Please retain this handbook in case you need to refer to any of the information in the future. Your magnetic filter comes with a 12-month guarantee, so should it develop a fault within this period, you should, in the first instance contact your seller where the item was purchased.

This guarantee specifically excludes losses caused by:

-Misuse or abuse

-Modified or tamped

-Accidental damage

-Failure to follow the installation instruction

This guarantee does not affect your statutory rights. For any enquiry relating to the guarantee please refer to your retailer.

Important Information:

1.Installation should be carried out by a qualified professional or other fully competent person.

2.Please check that all components are present. If there are any missing or damaged parts,

please contact your supplier immediately.

Component Parts:

1.lsolating valve

2.Diverter filter fitting

3.Union cap

4.Drain valve

5.Filter lower body

6.Strainer

7.Filter upper body

8.Air bleed valve

9.Magnetic rod

10.Multi-function wrench

Technical Characteristic:

1.Inlet: G3/4

2.Outlet: G3/4

3.Maximum Temperature: 95°C 100

4.Volume: 200ML

5.Maximum Pressure: 10 bar

6.Magnetic: 10000 Gauss LIL

7.Flow Rate lence

Installation Instructions:

Only competent people such as qualified heating engineer should install the device.

1.Locate a suitable site for the filter to allow access and servicing. Return pipe is recommended, do not fit it between the boiler and the overflow on the open vented systems.

2.Release and drain the heating system pressure.

3.Mark the pipe, using a suitable tool to cut out the marked section and remove burr.

4.Fit the isolating valves provided onto both inlet and outlet of the pipes in the heating system flow. Fit the diverter using the provided flat washers, and tighten the inner nut fully. After that, tighten the outer compression nuts on valves to ensure a watertight seal.

5. Fit the filter body to the diverter with enough strength, and hand tightening the locking collar (do not over tighten). Filter body must be installed vertically.

6. Open the isolation valves and turn on the heating system.

7. Vent as required by using the top air bleed valve.

Annual Maintenance Requirements:

To maintain optimum efficiency, annually cleaning is recommended.

1.lsolate the heating system and close both of the two isolating valves. Prepare a suitable bucket to collect spillage.

2.Remove the magnetic rod and open the drain valve. Put it into the bucket.

3.If there are too many impurities, open the isolating valve (inlet water end) and rinse with the inlet water.

4.A major annual cleaning is recommended. Open the lower body of the magnetic filter with a multi-function wrench. Remove the strainer, and clean by soapy water.

5.Put in the magnetic rod and strainer after cleaning. Tighten upper and lower bodies (top bleed valve should be in the upper position). Slightly open the inlet valve and the bleed valves until all air is removed. Close bleed valve then open fully both inlet and outlet valves and check for any leaks.

6.Start the heating system.

[3]

WARNING: Please observe the safety instructions provided in this document. This filter contains a strong magnet. Care and attention should be taken at all times during installation and servicing. Do not place the magnetic core on any ferrous surfaces or near ferrous items.

Chemical Dosing:

1.lsolate the boiler and close both isolating valves. Release air pressure by opening the top air bleed valve.

2.Drain the filter fully: Please bucket to collect the water and undo the bleed valve. Once the water has been drained replace the bleed valve.

3.Does chemicals through the open filter top once complete then hand tighten the bleed valve in the filter top.

4.Slightly open the inlet valve and the bleed valves until all air is removed. Close bleed valve then open fully both inlet and outlet valves and check for any leaks.

5.Turn on the heating system to flush, vent system is required.

Attention: Do not allow the chemicals to remain static in the filter for long.

Trouble Shooting and Problem Solving:

Problem 1: Water is leaking from the filter

Solution: Turn off the system, close the isolating valves. Preform the following checks:

a. Check all seals for location and condition.

b. Check the isolating valve nuts to ensure they are fully tightened.

c. Check the converter locking collar is firmly tightened and not cross threaded.

Problem 2: Poor flow through filter

Solution: Clean the filter when reduced flow is noted.

MS this marking indicates that this product should not be disposed with other household wastes throughout the EU. To prevent possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to promote the sustainable reuse of material resources. To return your used device, please use the return and collection systems or contact the retailer where the product was purchased. They can take this product for environmentally safe

recycling.